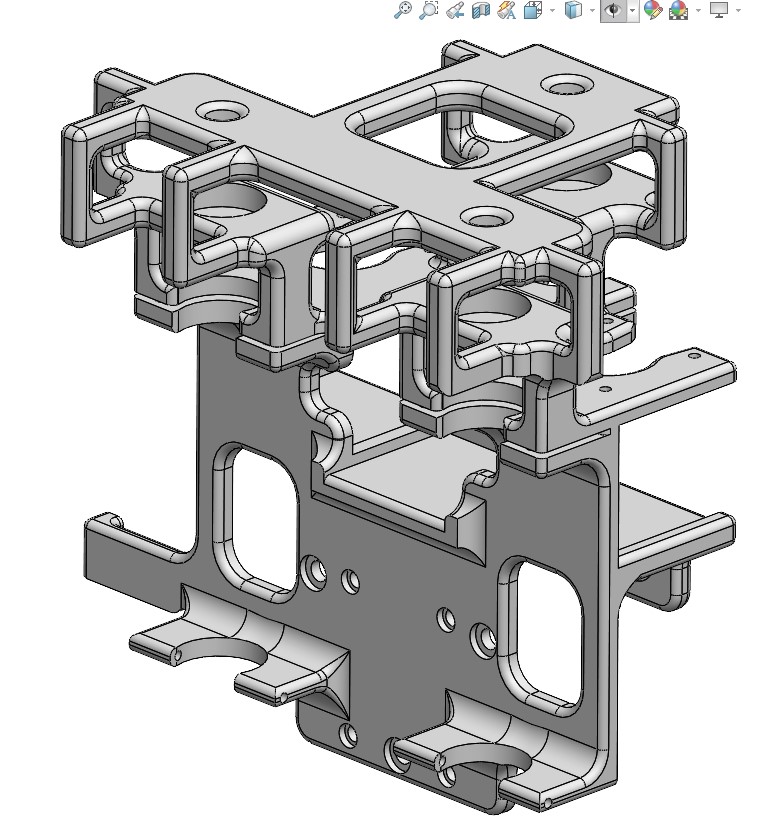

An inexpensive multi-material extrusion system was developed for electronics sensor printing. The fixture shown in fig (1) and its components like gears, and plunger attachments were designed in SoildWorks and 3D printed using PLA. These components were assembled over the X axis gantry of commercially available three extruder Geetech 20T FDM printer replacing it’s hot-end.

Bearings, stepper motor, lead screw, and appropriate size 30ml syringes were then assembled on the fixture. This design was developed keeping in mind maximizing available print bed area. Gear ratio was implemented for the same and also to achieve higher torque to ooze functional ink with high viscosity.